Recycled collision parts are gaining popularity in the automotive industry as a sustainable and cost-effective solution for paintless dent repair. Sourced from crashed vehicles, these parts undergo rigorous recycling processes to recover materials, reducing waste and offering an eco-friendly alternative to traditional manufacturing. By adopting recycled collision parts, auto body shops contribute to a circular economy, accessing high-quality components at lower costs without sacrificing performance or durability. This method minimizes the demand for new materials and energy-intensive production, benefiting both the environment and budget-conscious consumers seeking reliable painting solutions.

In today’s eco-conscious world, the automotive industry is undergoing a transformation. One innovative solution gaining traction is the utilization of recycled collision parts for paintless dent repair jobs. This sustainable approach not only reduces waste but also offers numerous advantages, such as cost savings and faster turnaround times. By embracing recycled collision parts, auto repair shops can contribute to a greener future while delivering high-quality, efficient services.

- Understanding Recycled Collision Parts: A Sustainable Approach to Auto Repair

- Benefits of Using Recycled Collision Parts for Paintless Dent Repair

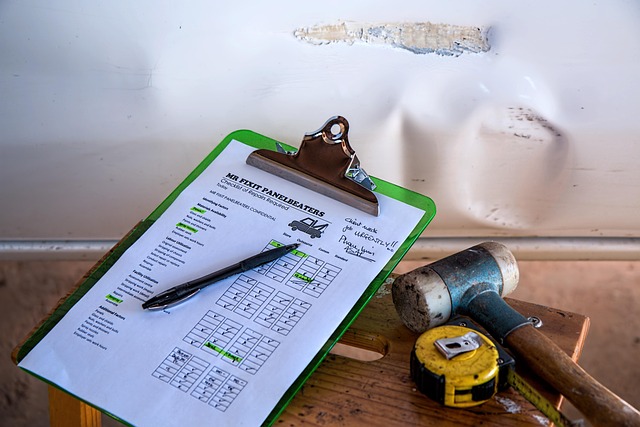

- The Process: How Recycled Collision Parts Enable Efficient and Eco-Friendly Repairs

Understanding Recycled Collision Parts: A Sustainable Approach to Auto Repair

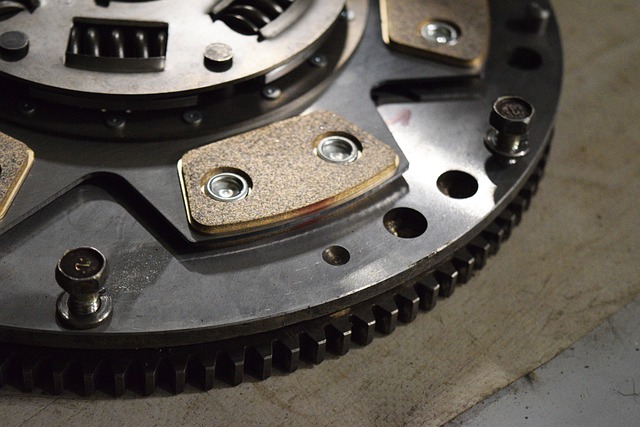

Recycled collision parts are a growing trend in the automotive industry, offering a sustainable and cost-effective solution for auto repairs, particularly in paintless dent repair jobs. These parts, sourced from vehicles that have been involved in collisions or accidents, undergo a meticulous recycling process to recover and reuse materials. This approach not only reduces waste but also provides an eco-friendly alternative to traditional manufacturing methods.

By utilizing recycled collision parts, automotive repair shops can contribute to a more circular economy. It allows them to access high-quality components at a lower cost without compromising on performance or durability. This method is especially beneficial for vehicle paint repair, as it minimizes the need for new materials and the energy-intensive processes involved in their production. Thus, recycled collision parts present a win-win scenario for both the environment and budget-conscious consumers seeking reliable auto painting solutions.

Benefits of Using Recycled Collision Parts for Paintless Dent Repair

Using recycled collision parts for paintless dent repair offers numerous environmental and economic benefits. By opting for reused components, auto body shops can significantly reduce waste and lower their carbon footprint. This eco-friendly approach not only conserves natural resources but also minimizes the energy consumption associated with manufacturing new parts. Moreover, recycled collision parts are often more affordable than their virgin counterparts, making them a cost-effective solution for car dent repair and auto body restoration projects.

Additionally, these refurbished parts maintain high quality standards, ensuring that paintless dent repair jobs are just as durable and reliable as those using brand new materials. The process involves meticulous inspection and refurbishment, guaranteeing that the restored components meet or exceed original specifications. This attention to detail results in seamless integration of the recycled parts into the car body, contributing to a flawless restoration and a satisfied customer experience, all while promoting sustainable practices in the automotive industry.

The Process: How Recycled Collision Parts Enable Efficient and Eco-Friendly Repairs

The process of using recycled collision parts for paintless dent repair is a game-changer in the automotive industry, offering both efficiency and environmental benefits. These parts, sourced from damaged vehicles, undergo rigorous sorting and recycling methods to reclaim valuable materials, reducing waste that often ends up in landfills. By utilizing this sustainable approach, auto body work professionals can provide high-quality vehicle repair services with a minimized ecological footprint.

Recycled collision parts enable quick and precise repairs, as the standardized dimensions and specifications ensure compatibility with various vehicle models. This streamlines the paintless dent repair process, allowing technicians to focus on more intricate work. Moreover, the availability of these recycled components can reduce lead times compared to traditional ordering processes, making it a cost-effective solution for both repair shops and customers seeking swift auto body repairs without compromising quality or contributing to environmental degradation.

Recycled collision parts are not only a sustainable solution but also an efficient and cost-effective choice for paintless dent repair. By utilizing these reprocessed materials, auto repair shops can reduce their environmental impact while providing high-quality repairs. This eco-friendly approach allows for faster turnaround times, less waste generation, and significant cost savings without compromising on aesthetics or structural integrity. Embracing recycled collision parts is a step towards a greener future for the automotive industry.